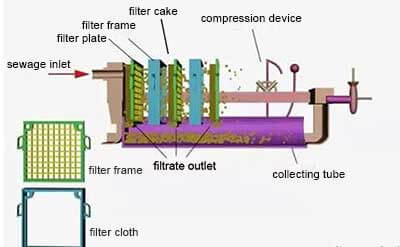

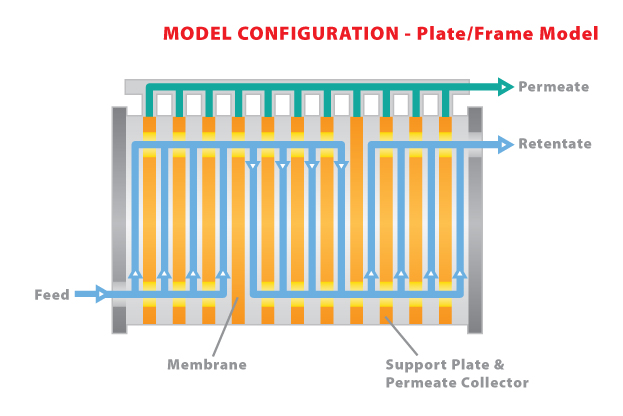

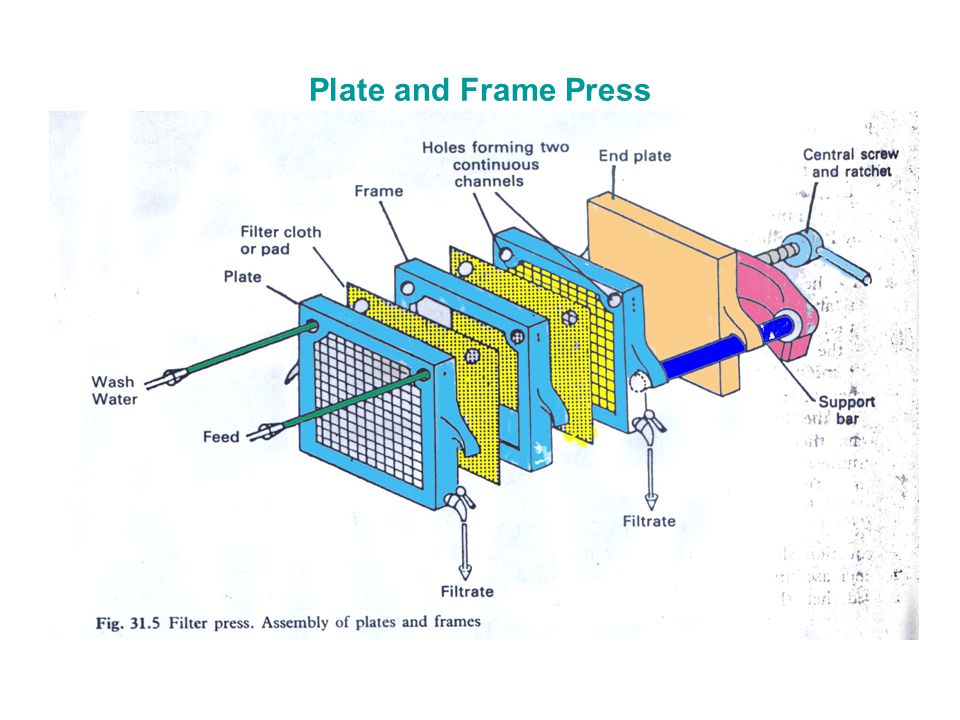

A plate and frame filter press is the most fundamental design and may be referred to as a membrane plate filter this type of filter press consists of many alternating plates and frames assembled with the supports of a pair of rails with filter membranes inserted between each plate frame pair.

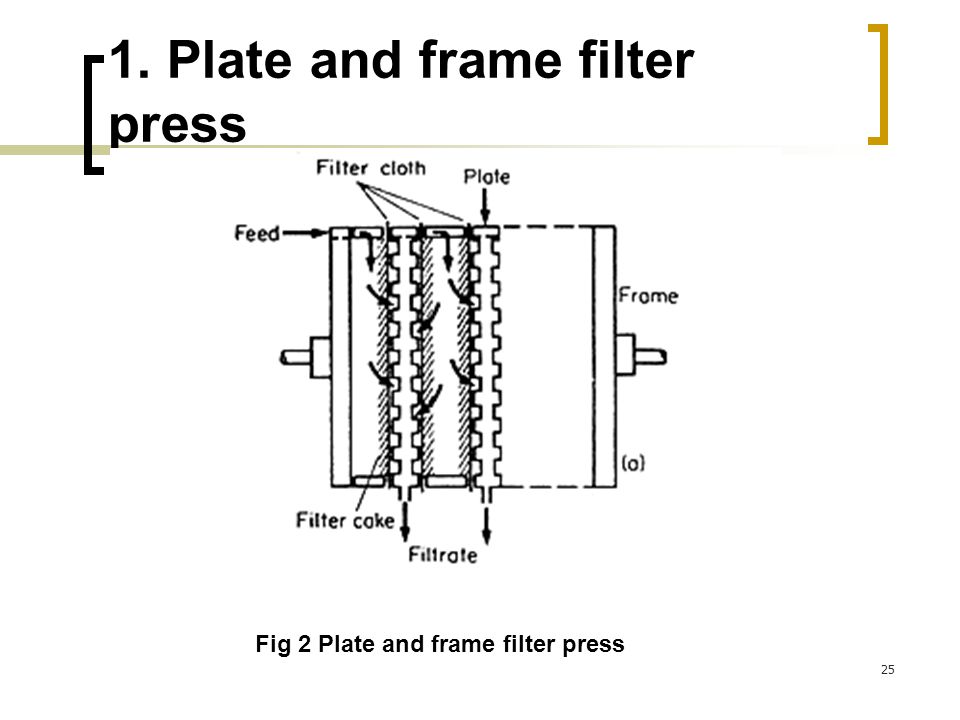

Plate and frame filter press simple diagram.

By mating two recessed chamber plates or by two flush plates with a cake frame much like a picture frame sandwiched in between.

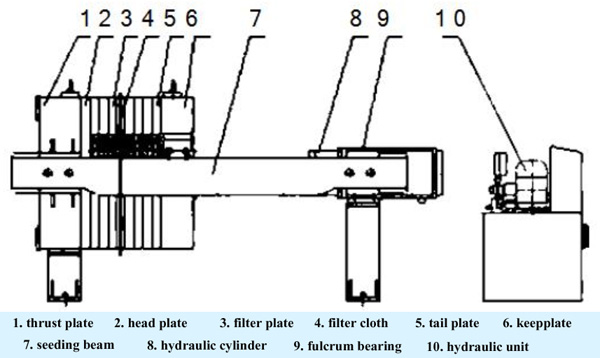

A filter press consists of a series of chambers containing square or rectangular filter plates supported in a frame.

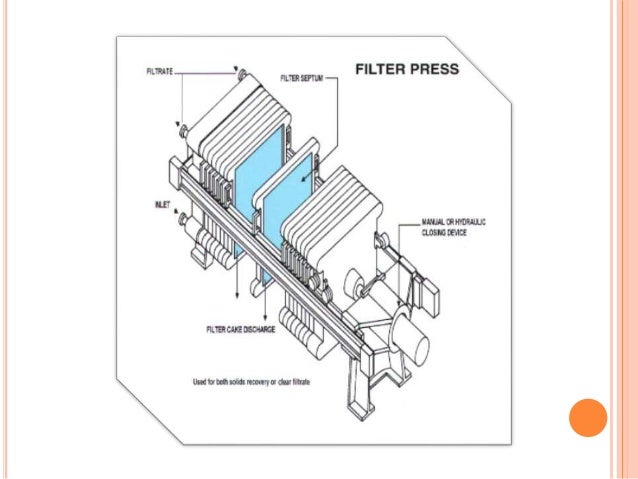

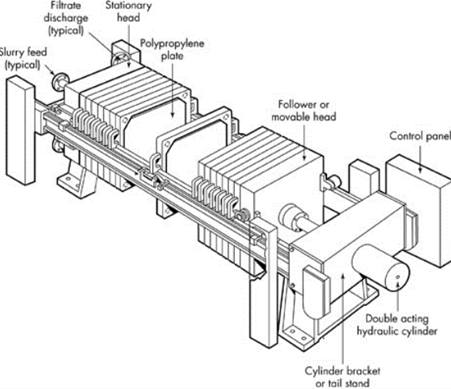

This clamping is done by either an old style wheel crank or more modernly with a hydraulic pump and cylinder either manual or automatic.

Unipack s plate frame type filter press is a sterlisable sheet filter press mosel for clarifying and sterilizing filtration with square model of filter elements.

Frame of a filter press feeding supporting beam plates sidebars mobile supporting beam cylinder hydraulic unit sturd mechanically welded frame alowing an even distribution of the stress for a nominal pressure of 7 up to 15 bars.

The filter is free standing the plate pack being completely clear of the ground and is completely encased in stainless steel sheet.

Filter presses can be built in a wide range of sizes from small lab scale 150 mm presses to those with much larger capacities such as those with 1500 and 2000 mm filter plates.

Filter press is simply a kind of machine which performs filtration separation during its press operation.

See full capacities chart below.

The plate and frame design utilizes a flat solid plate known as a flush plate covered by a filter press cloth with a hollow frame between each plate.

The plate and frame press is the most fundamental design and the oldest type of filter press the design is a skeleton made of metal that holds and clamps the filter plates together to form a pressure chamber.

Plate and frame filter press design overview.

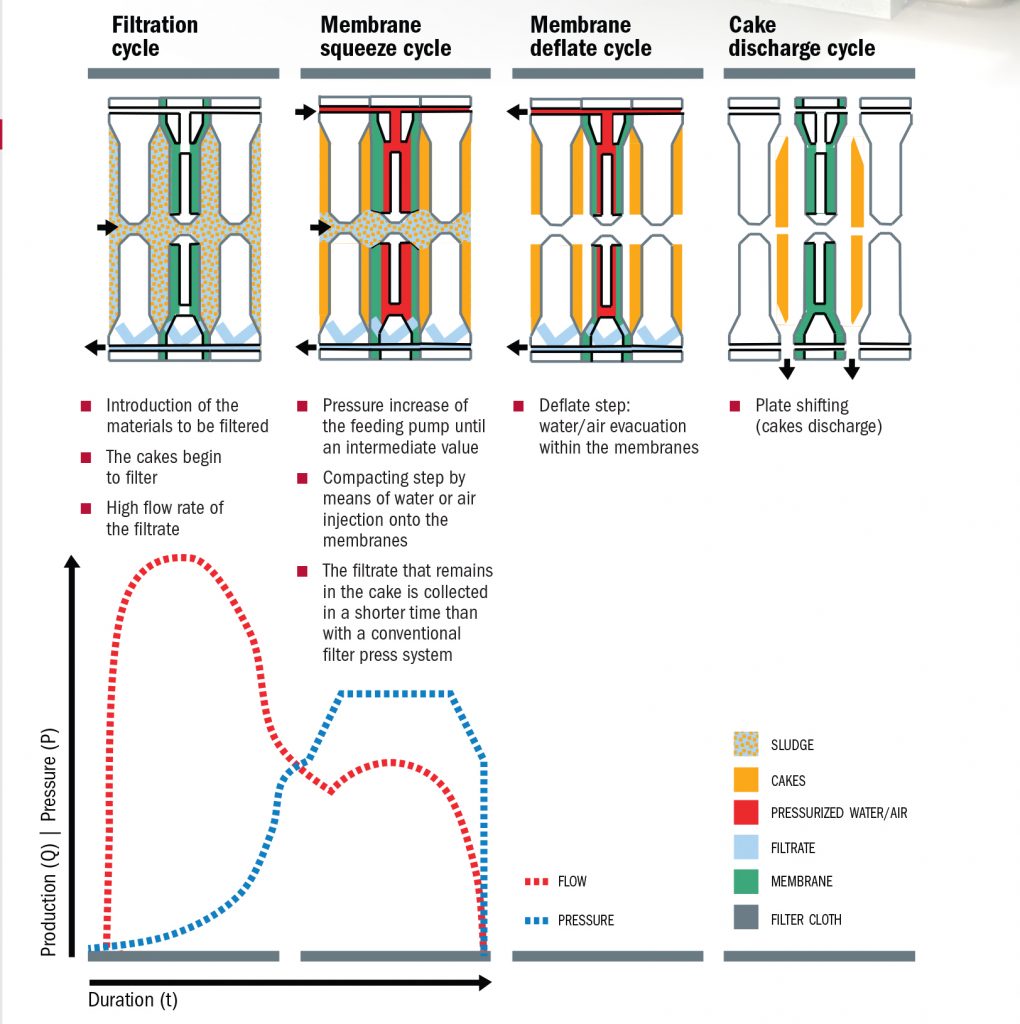

Shows press fill membrane squeeze cake blow and core blow process for dewatering mine tailings mineral concentrations fly ash are other products.

Sizes and types of filter presses offered.

The two faces of the filter plate have a drainage surface in the form of ribs grooves or pips to allow filtrate to drain behind the cloth to the drainage.

Once the filter chambers are loaded with slurry the plates are forced together with hydraulic rams that generate.

The filter cake chambers are formed in either of two ways.

Lateral sidebars takes back the tensile stress and support the plates and plate shifting trolleys.